The Role of Ultrasonic Welding in Electronics Manufacturing

Ultrasonic welding has turned into a vital strategy in the hardware fabricating industry, offering accuracy, effectiveness, and unwavering quality in the get together of electronic parts. This cycle uses high-recurrence ultrasonic vibrations to make solid and sturdy welds between materials, making it especially significant in delivering many-sided electronic gadgets. Here is a top to bottom glance at how ultrasonic welding assumes a pivotal part in hardware producing.

Grasping Ultrasonic Welding

Ultrasonic welding is areas of strength for a welding cycle where high-repeat ultrasonic vibrations are used to join materials. The cooperation incorporates applying these vibrations to the association point between two materials under strain, making restricted heat due to crushing. This power makes the materials smooth and bond without the necessity for additional fillers or fix.

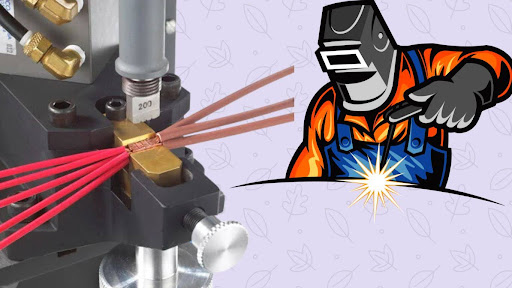

The cooperation generally works at ultrasonic frequencies going from 20 kHz to 70 kHz. The stuff used in ultrasonic welding consolidates a generator to make ultrasonic vibrations, a transducer to change over electrical energy into mechanical vibrations, and a sonotrode (or horn) that focuses the vibrations onto the materials being welded. The blend of these parts engages the specific control fundamental for welding touchy electronic parts.

Benefits of Ultrasonic Welding in Gadgets Assembling

Accuracy and Exactness: One of the fundamental benefits of ultrasonic welding is its precision. The cycle can get minuscule and convoluted parts together with high accuracy. This is particularly advantageous in devices creating, where parts like computer processors, connectors, and wires are oftentimes extremely microscopic. The ability to weld these parts with precision ensures that electronic devices capacity precisely and reliably.

Speed and Proficiency: Ultrasonic welding is known for its speed. The cycle is a ton faster diverged from regular welding strategies, as it can make solid areas for an in milliseconds. This quick welding limit considers high creation rates, which is principal in the equipment business where colossal volumes of parts are conveyed. The capability of ultrasonic welding also adds to reducing for the most part creating costs.

No Requirement for Extra Materials: Not at all like other welding techniques that require fillers, advances, or fix, ultrasonic welding shouldn’t for a second worry about any additional materials. This enhances the gathering framework as well as ensures that the welds are awesome and freed from toxins. This is particularly critical in equipment creating, where the presence of new materials can provoke separating or disillusionment of electronic contraptions.

Reduced Thermal Impact: Customary welding strategies frequently include huge intensity that can harm delicate electronic parts. Ultrasonic welding, then again, produces limited heat just at the weld interface, limiting the gamble of warm harm to the encompassing regions. This is urgent for keeping up with the respectability of fragile electronic parts during the get together cycle.

Environmental Considerations: Ultrasonic welding is a harmless to the ecosystem interaction. It doesn’t create unsafe emanations or waste materials, which makes it a more practical choice contrasted with other welding strategies that depend on transitions or synthetics. This lines up with the developing accentuation on green assembling rehearses inside the hardware business.

Applications in Electronics Manufacturing

Ultrasonic welding finds various applications in gadgets producing, mirroring its flexibility and adequacy:

Wire Bonding: In the gathering of electronic gadgets, ultrasonic welding is regularly utilized for wire holding. This interaction includes joining fine wires to semiconductor chips or different parts. Ultrasonic welding guarantees major areas of strength for a between the wires and the part, which is urgent for the dependable exhibition of the gadget.

Connector Assembly: Ultrasonic welding is utilized to collect connectors and terminals in electronic gadgets. The cycle makes areas of strength for a tough association between various pieces of the connector, guaranteeing solid electrical conductivity and mechanical soundness.

Battery Manufacturing: In the development of batteries, ultrasonic welding is utilized to join battery tabs to cathodes. The accuracy and speed of ultrasonic welding add to the proficient gathering of battery packs, which are utilized in many electronic gadgets.

Plastic Component Joining: Ultrasonic welding is likewise used to join plastic parts in electronic gadgets. This is especially helpful in making fenced in areas or lodgings for electronic parts. The cycle guarantees major areas of strength for a perfect weld without harming the plastic parts.

Challenges and Future Trends

Notwithstanding their benefits, ultrasonic welding machines face a few difficulties. The underlying expense of the gear can be high, and exact control is expected to accomplish ideal outcomes. Moreover, ultrasonic welding may not be appropriate for all materials or applications, especially those including extremely thick or high-liquefying point materials.

In any case, progressing headways in ultrasonic welding innovation are tending to these difficulties. Developments, for example, further developed transducer plans, upgraded control frameworks, and better cycle observing are growing the abilities of ultrasonic welding machines. As hardware keep on developing, ultrasonic welding machines will probably assume an undeniably basic part in the assembling of cutting edge and scaled down electronic gadgets.

Conclusion

Ultrasonic machines have turned into a foundation of present day gadgets fabricating, offering unequaled accuracy, speed, and effectiveness. Their capacity to make solid and dependable welds without extra materials or huge intensity makes them essential in the development of sensitive electronic parts. As innovation advances, ultrasonic welding machines will keep on driving development and effectiveness, forming the eventual fate of gadgets producing and guaranteeing the dependability of cutting edge electronic gadgets.