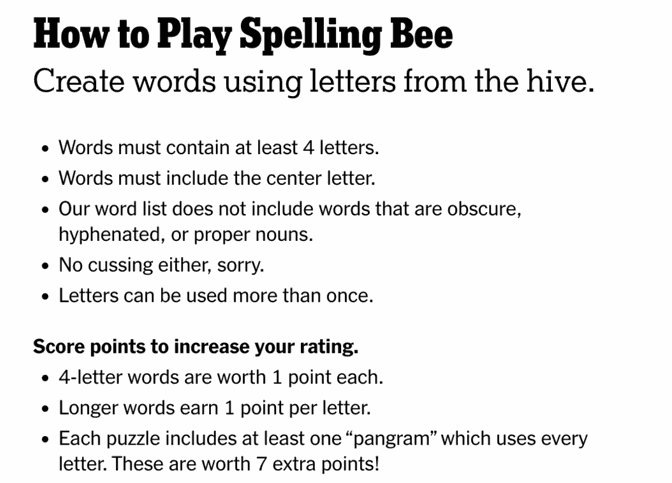

Strengthen Your Warehouse Safety: How Rack Inspections Help

Introduction

Warehouse safety is a crucial aspect of managing any storage facility. Ensuring that all systems, particularly racking systems, function correctly is paramount. Frequent rack inspections Cincinnati OH, are essential for preserving these systems’ integrity and averting mishaps at work. By inspecting racks consistently, warehouses can identify potential issues before they lead to severe problems.

Without routine inspections, warehouses risk structural breakdowns, which can cause serious injuries or even fatalities. These inspections ensure that all components are in good condition and capable of handling their designed loads. Therefore, understanding the significance of these inspections and maintaining a routine can safeguard your employees and inventory, ultimately enhancing overall operational efficiency.

Why Rack Inspections Are Crucial

Racking systems are crucial in warehouse operations, supporting product weight and optimizing storage space. However, neglect can lead to hazards, such as warehouse accidents, which can disrupt operations and lead to financial losses. Common types of accidents include falling objects or collapsing racks. Routine inspections are essential to identify and address these issues early, preventing catastrophic failures and maintaining smooth operations. Addressing unnoticed damage can prevent catastrophic failures.

Common Issues Found in Racking Systems

Racking systems can be damaged due to factors like forklifts, overloading, or natural wear and tear. Regular inspections can detect these damages early and take corrective action. Incorrect installation can lead to uneven weight distribution and shaky systems, increasing the risk of collapse. Issues like missing bolts, improperly anchored bases, or misaligned beams can go unnoticed but are critical to the rack’s stability. Overloaded racks can cause bending or breaking, compromising the structure’s integrity. Regular inspections can help prevent hazards and ensure warehouse safety by checking load distribution and adhering to recommended weight limits.

Best Practices for Maintaining Your Racking Systems

Regular maintenance routines, training for warehouse staff, and immediate repair of identified issues are crucial for maintaining a safe and efficient working environment. Regular inspections and detailed records of maintenance activities help catch and address issues before they become severe. Staff should be educated on weight limits and safe loading and unloading materials and encouraged to report and respond promptly. Protective components like safety netting, column guards, and back mesh can also enhance the safety and stability of racking systems. Implementing these measures reflects a comprehensive approach to warehouse safety, considering all potential risks and mitigating them effectively.

The Role of Professional Inspections

Hiring qualified professionals for regular assessments is essential for ensuring the optimal condition of racking systems. These professionals have the expertise to identify potential hazards. They are well-versed in the latest safety standards, ensuring full compliance and optimal safety. Investing in professional inspections can save money, prevent costly accidents, and provide peace of mind, as they often reveal minor faults that could escalate into major ones.

Real-Life Case Studies

A distribution center implemented regular rack inspections, reducing accidents and maintenance costs. This proactive approach improved safety, employee morale, and productivity. However, another company faced severe financial and legal repercussions due to a racking system collapse. Lessons from these incidents emphasize the importance of ongoing maintenance and vigilance. By learning from real-life scenarios, companies can adopt best practices and avoid similar pitfalls, ensuring a safer and more efficient working environment.

Conclusion

Regular inspections are crucial for maintaining warehouse safety and efficiency. By adhering to best practices, using professional inspections, and promptly addressing issues, warehouses can mitigate risks, protect their workforce, and ensure smooth operations. Investing in safety is essential for the future of your warehouse, contributing to a safer working environment and preventing costly incidents.

For more on this content, visit the rest of our blog!