A Comprehensive Guide to Heavy Duty Conveyor Rollers

Heavy-duty conveyor rollers are essential components in industries that require the handling of large, heavy materials. These rollers are designed with robust construction and high load capacity to withstand the rigorous demands of heavy industrial applications. Commonly made from durable materials such as steel, stainless steel, reinforced plastics, and nylon, heavy-duty conveyor rollers ensure reliable and efficient transportation of materials in environments like mining, quarrying, construction, demolition, and large-scale manufacturing. Their significance in heavy industry lies in their ability to enhance operational efficiency, reduce manual labor, and improve safety by handling substantial loads with ease. Understanding the features and applications of these rollers is crucial for optimizing industrial processes and ensuring long-term productivity.

What Are Heavy Duty Conveyor Rollers?

Definition and Features:

Heavy-duty conveyor rollers are specialized conveyor rollers designed to support and transport large, heavy loads in industrial settings. These rollers are a critical component of conveyor systems used in industries such as mining, construction, and manufacturing. They are engineered to handle the rigors of transporting substantial weights, ensuring smooth and efficient movement of materials. Key features of heavy-duty conveyor rollers include:

Robust Construction: Heavy-duty rollers are built with a robust structure to withstand the mechanical stresses and impacts associated with handling heavy loads. This construction ensures that the rollers remain reliable and functional even under continuous and demanding use.

High Load Capacity: These rollers are designed to support significantly higher weights compared to standard rollers. They can handle loads ranging from several hundred to thousands of pounds, depending on the specific requirements of the application. This high load capacity is crucial for industries that deal with large and heavy items on a regular basis.

Typical Materials Used:

The materials used in the construction of heavy-duty conveyor rollers play a vital role in their performance and durability. Common materials include:

Steel: Steel is a popular choice for heavy-duty rollers due to its exceptional strength and durability. Steel rollers can handle extreme loads and are resistant to wear and impact. They are often used in environments where robustness and longevity are paramount.

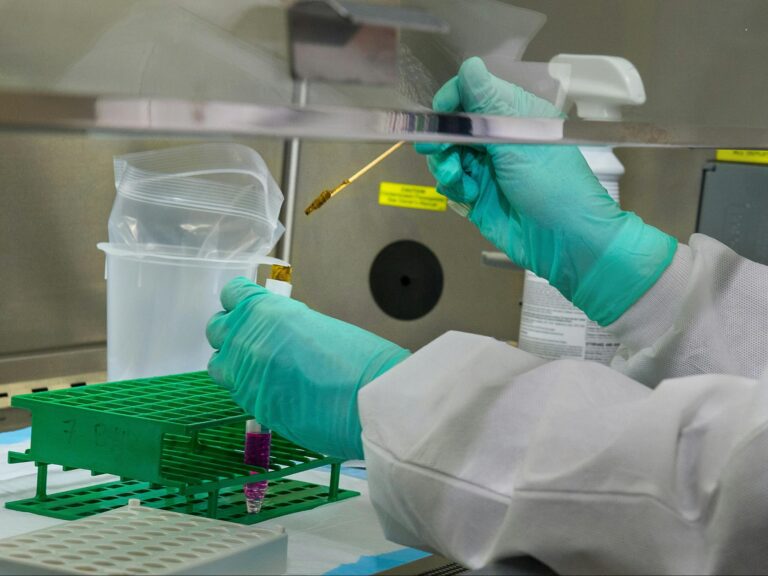

Stainless Steel: Stainless steel rollers offer similar benefits to steel rollers but with added resistance to corrosion and rust. This makes them ideal for applications in harsh environments or where exposure to moisture and chemicals is common. Stainless steel rollers are frequently used in the food processing and pharmaceutical industries for their hygiene and corrosion resistance.

Reinforced Plastics: Reinforced plastic rollers combine the lightweight properties of plastics with added strength and durability from reinforcing materials such as glass fibers. These rollers are resistant to corrosion and chemical exposure, making them suitable for specific industrial applications where reduced weight and chemical resistance are desired.

Nylon: Nylon conveyor rollers are known for their lightweight, low friction, and excellent wear resistance. They are suitable for applications that require a balance of strength and reduced weight. Nylon rollers also offer good chemical resistance and can operate quietly, making them ideal for various industrial environments.

Heavy-duty conveyor rollers are essential for handling substantial loads in industrial applications. Their robust construction and high load capacity ensure reliable performance under demanding conditions. Made from materials such as steel, stainless steel, reinforced plastics, and nylon, these rollers are designed to meet the specific needs of various industries, providing durability, efficiency, and long-term operational benefits. Understanding the definition, features, and materials of heavy-duty conveyor rollers is crucial for selecting the right rollers to optimize industrial processes.

Industrial Applications of Heavy Duty Conveyor Rollers

Heavy duty conveyor rollers are indispensable in various industrial sectors due to their ability to handle large and heavy loads efficiently. Their robust design and high load capacity make them suitable for a wide range of applications, enhancing productivity and operational efficiency. Here’s a detailed look at some key industrial applications:

Mining and Quarrying:

In the mining and quarrying industries, heavy duty conveyor rollers are critical for handling large rocks, minerals, and other raw materials. These industries operate in harsh and demanding environments where robust and durable equipment is essential.

Handling Large Rocks and Minerals: Mining operations involve the extraction and transportation of massive rocks and mineral ores. Heavy duty conveyor rollers are designed to withstand the extreme weight and abrasive nature of these materials. The rollers facilitate the smooth and continuous movement of extracted materials from the mining site to processing facilities, reducing manual labor and improving operational efficiency.

Durability in Harsh Conditions: The rugged construction of heavy duty rollers ensures they can endure the tough conditions typical in mining environments, such as dust, dirt, and constant impact from heavy materials. This durability minimizes downtime and maintenance costs, contributing to uninterrupted production processes.

Construction and Demolition:

In the construction and demolition sectors, heavy duty conveyor rollers play a crucial role in transporting heavy debris, building materials, and demolition waste. These industries require equipment that can handle substantial loads and operate reliably in challenging environments.

Transporting Heavy Debris and Materials: Construction projects involve the movement of large quantities of materials like concrete, steel beams, and construction waste. Heavy duty conveyor rollers facilitate the efficient transfer of these materials across the site, reducing the reliance on manual handling and enhancing safety.

Robustness for Demolition Tasks: During demolition, heavy duty rollers are used to convey broken concrete, metal scraps, and other debris. Their robust design ensures they can manage the impact and abrasiveness of demolition waste, providing reliable performance throughout the demolition process.

Manufacturing and Warehousing:

Manufacturing and warehousing operations often require the movement of large and heavy components, which can be efficiently managed with heavy duty conveyor rollers. These rollers support high load capacities and offer smooth and reliable transportation solutions.

Movement of Large and Heavy Components: In manufacturing plants, heavy duty conveyor rollers are used to transport large parts and assemblies between different production stages. They ensure that heavy items are moved quickly and safely, reducing bottlenecks and increasing throughput.

Efficient Material Handling in Warehouses: Warehousing operations involve the storage and retrieval of heavy goods. Heavy duty rollers enable the efficient handling of pallets, crates, and other large items, streamlining inventory management and order fulfillment processes. Their ability to support heavy loads ensures that goods are transported without risk of damage or system failure.

Heavy duty conveyor rollers are vital components in mining, quarrying, construction, demolition, manufacturing, and warehousing industries. Their robust construction and high load capacity allow them to handle the demanding tasks associated with these sectors, ensuring efficient and reliable material handling. By facilitating the smooth movement of large and heavy items, heavy duty rollers enhance productivity, reduce labor costs, and improve overall operational efficiency. Understanding the specific applications of these rollers helps industries select the right equipment to meet their needs and achieve optimal performance.

Key Factors in Selecting Heavy Duty Conveyor Rollers

Selecting the right heavy-duty conveyor rollers is crucial for ensuring the efficiency, reliability, and longevity of conveyor systems in demanding industrial applications. Here’s an in-depth look at the key factors to consider:

Load Capacity and Durability:

One of the most critical factors in selecting heavy-duty conveyor rollers is ensuring that they have the appropriate load capacity and durability for the intended application.

Importance of Matching Roller Capacity to Load: The load capacity of the rollers must match or exceed the maximum weight they will be required to support. This includes the weight of individual items, combined loads, and any dynamic forces that may occur during operation. Overloading rollers can lead to premature wear, deformation, or failure, causing costly downtime and repairs. Therefore, it is essential to accurately calculate the maximum load requirements and select rollers that are designed to handle these weights reliably.

Durability: Heavy-duty rollers are subject to continuous and rigorous use, often in harsh environments. Selecting rollers made from robust materials such as steel, stainless steel, or reinforced plastics ensures they can withstand the physical stresses and impacts encountered during operation. Durability also includes resistance to wear and tear, which extends the lifespan of the rollers and reduces the frequency of replacements.

Environmental Conditions:

The environmental conditions in which the conveyor rollers will operate play a significant role in their selection. Different environments pose unique challenges that must be addressed to maintain optimal performance.

Considerations for Extreme Temperatures: In environments with extreme temperatures, whether high or low, it is crucial to choose rollers made from materials that can withstand thermal stress without compromising their structural integrity. For example, steel and stainless steel rollers perform well in a wide temperature range, while some reinforced plastics and nylon rollers are designed for specific temperature tolerances.

Moisture and Chemical Exposure: In industries where rollers are exposed to moisture, chemicals, or corrosive substances, materials like stainless steel or specific grades of reinforced plastics and nylon are ideal. These materials resist corrosion and chemical degradation, ensuring long-term functionality and reducing the need for frequent replacements due to environmental damage. Additionally, selecting rollers with sealed bearings or protective coatings can enhance their resistance to these harsh conditions.

Maintenance and Longevity:

Minimizing maintenance requirements and maximizing the service life of conveyor rollers are essential for cost-effective and efficient operations.

Choosing Rollers That Require Minimal Maintenance: Rollers that require less frequent maintenance contribute to lower operational costs and reduced downtime. Look for features such as self-lubricating bearings, sealed bearings, and materials that are resistant to wear and corrosion. These features help ensure that the rollers can operate smoothly for extended periods without the need for regular maintenance.

Long Service Life: The overall longevity of the rollers is influenced by their construction quality, material properties, and design. High-quality materials such as hardened steel, stainless steel, and reinforced plastics can withstand the rigors of heavy-duty use. Additionally, well-designed rollers with features like precision bearings and robust axles ensure consistent performance over a long service life. Investing in durable rollers may have a higher upfront cost but can lead to significant savings over time due to reduced replacement and maintenance costs.

Selecting the right heavy-duty conveyor rollers involves careful consideration of load capacity, durability, environmental conditions, and maintenance requirements. Matching the roller capacity to the expected load, choosing materials that withstand specific environmental challenges, and opting for rollers that require minimal maintenance and offer long service life are essential steps. By focusing on these key factors, industries can ensure that their conveyor systems operate efficiently, reliably, and cost-effectively, ultimately enhancing overall productivity and reducing operational expenses.